Global leaders agree on significant steps to address the growing environmental damage caused by plastic waste

At the 5th UN Environment Assembly Summit on waste management Global leaders have agreed on actions to combat the environmental impact of plastic packaging pollution. At the summit, which was held in Nairobi at the beginning of March, world leaders approved two major proposals focused on eliminating plastic pollution as part of fourteen resolutions that were agreed.

Marine Pollution & Lifecycle of Plastics

Japan led a proposal that focused on marine pollution. The 27 EU participants were among more than 70 countries who supported a further proposal that puts in place significant measures to control the full lifecycle of plastics

The US and France made a joint statement before the summit to demonstrate commitment to a whole-of-lifecycle system for plastic waste management. The statement emphasized the need for actions that will protect the environment for future generations

Legislation To End Plastic Pollution

The UN described the summit as the most important green deal since the Paris accord. The new resolutions have significant implications for all manufacturers and users of plastic products. The summit proposals for legislation controlling plastic waste emphasized the importance of good design principles that reduce waste, and the necessity for effective recycling.

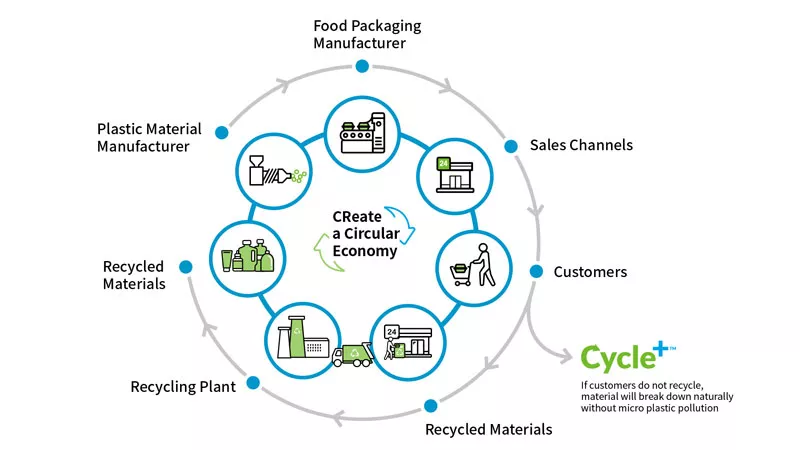

At the summit, world leaders agreed “to forge an international legally binding agreement to end plastic pollution” including building a more robust “circular economy” to assist in this goal. The proposed circular economy for plastic products will be achieved through improvements in design, manufacture, and recycling.

A Better Plastic Economy By Design

Improved design principles are a key success factor in the UN goals to eliminate plastic pollution. Design is critically important in achieving the UN resolutions because it has an impact on all stages of the plastic life-cycle. Better designs focus on the three biggest problems of plastic pollution today.

- Minimizing Use of Plastics

- Using Easily Recycled Materials

- Eliminating Microplastic Waste

Minimizing Use of Plastics

Improvements in design can enable the manufacture of products that use less material without compromising on strength and utility. At South Plastic we constantly innovate to find solutions to our customer’s packaging needs that use the absolute minimum of plastics required to achieve the same rigidity and strength of conventional products.

Careful choice of materials and structural redesign have enabled us to make material savings for our major customers without any reduction in visual appeal or performance. In fact, our innovative use of additives and coatings can improve the performance, for example with microwave safe and ultraclear containers, and still save on material needs.

Our inline production plastics recovery system already enables us to reduce plastic manufacturing waste by 34%, and we continue to innovate to improve our waste management processes.

Using Easily Recycled Materials

The technology to recycle all major plastic is very well established and understood. Still, however, we find unacceptable volumes of plastic going to landfill. Only 9% of all plastics that have ever been produced have been recycled. Combinations of plastics and difficulty in recognizing plastics or not having local recycling facilities that can treat them leads to consumers being unable to dispose of them properly.

We have focused on improvements in PP technology through better design and batch formulations as PP is one of the most readily recyclable plastics and is easy to sort, even from some mixed waste streams.

Our innovations in enhancing the clarity of PP as well as heat resistance mean we can equal or exceed the transparency of PET with high performance, recyclable PP. South Plastic leads the plastic packaging industry in building truly sustainable solutions to meet our customer needs.

Eliminating Microplastic Waste

At the top of the UN list of concerns is the increasing volume of microplastic waste entering the food chain. The majority of microplastics found in the world’s oceans come from the breakdown of non-biodegradable plastic packaging disposed of in landfill or directly into the sea. Microplastics have now been found in all the world’s oceans, even the Antarctic, and also in the food we eat.

The solution is to manufacture plastics that do not degrade into microplastics, but are readily broken down in the natural environment into environmentally harmless products. The increasing trend towards biodegradable plastics has been a welcome change in global approaches to plastic manufacture. Unfortunately studies have shown that the majority of ‘biodegradable’ plastics require specialist treatment, or still generate microplastic pollution.

South Plastic has partnered with Polymateria, a UK-based materials technology company that leads the world in finding truly biodegradable solutions to the plastic waste problem. Our Cycle+™ packaging products use Biotransformation technology, which is currently the only PAS 9017 certified process that ensures plastics break down under normal environmental conditions into harmless products without microplastic pollution.